|

| March 26, 2024 | Volume 20 Issue 12 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Top Tech Tip:

2D, 3D, or 2.5D? Choosing a vision system for your automation project

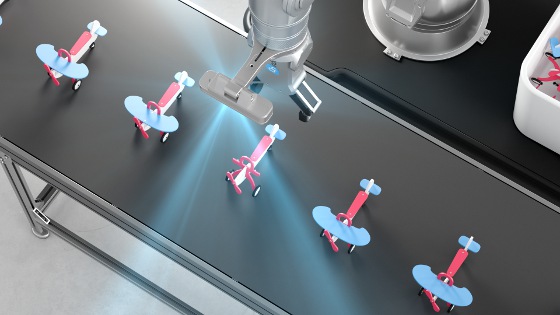

OnRobot's 2.5D Eyes vision system supports an enormous number of applications and is compatible with all leading robot brands. Here, Eyes helps during a palletizing task. [Credit: OnRobot]

By Kristian Hulgard, General Manager - Americas, OnRobot

Adding vision to your automation provides a boost to productivity, reduces waste, helps to ensure traceability, and improves quality. Vision systems are cropping up in all sorts of applications from inspection, measurement, and gauging to label verification, presence detection, and inventory control.

What else is new from OnRobot? OnRobot's D:PLOY solution is a software platform that ties all components in a robotics cell together -- including any leading cobot or light industrial robot arm along with tooling, sensors, and other devices -- making deployment up to 80% faster.

For example, machine vision can be used to inspect the quality of materials, detecting issues across a wide range of objects and materials from plastic bottles to cardboard and foil. Machine vision can also be used to ensure that cans and sealing caps are fitted correctly. Vision systems can also read barcodes and labels more quickly and effectively than any human.

Valued at $13.23 billion in 2021, the global machine vision market is expected to grow at a compound annual growth rate (CAGR) of 7.7% from 2022 to 2030 to reach $25.92 billion, according to Grand View Research. That's a lot of vision systems. It also means a growing range of products to choose from.

At the center of that decision is whether you choose to invest in a 2D, 3D, or 2.5D camera system. That choice will have a major impact on the cost and complexity of the deployment. It will also have an impact on the capabilities and functionality you can expect from the final application setup.

Matching your vision hardware to your application is important, but so too is making a decision that futureproofs your investment when new application requirements emerge.

As is so often the case across automation projects, the sweet spot for most situations is found in hardware that provides the best balance of usability, price, and functionality.

Seeing the world in 2D

2D vision systems are so-called because they can determine length and width (X and Y axis), but they are unable to determine height. This limits the number of applications and environments 2D systems can be successfully deployed in.

No pun intended, but 2D systems are a bit two-dimensional: They may be the least expensive type of camera available, but they are also the least versatile and provide the least functionality compared to 2.5D and 3D systems.

Moreover, 2D systems require perfect contrast to function correctly, and many engineering hours can be lost making minute adjustments to the lighting.

All of that said, 2D vision systems are proven to be effective across simple barcode reading, label orientation, and printing verification applications. However, if you have more ambitious plans for your use of vision, then 2D systems are going to come up short.

Seeing the world in 3D

True 3D cameras provide X, Y, and Z (height) information as well as rotational information around all three axes. These systems provide a wealth of highly accurate data -- so much data, in fact, that investment in 3D camera systems is overkill for the overwhelming majority of applications.

Certainly, if you're thinking about an advanced bin-picking application, or your application requires detailed information about a target object's precise location in space, along with its size, volume, surface angles, degrees of flatness, and other features, then a 3D vision system may be your only choice.

Don't expect fast deployment times, though, and remember that the advanced features of 3D cameras and vision systems come at a hefty cost.

Seeing the world in 2.5D

2.5D vision systems provide the X, Y, and Z information that's required to perform advanced vision-based tasks. 2.5D systems also provide information that enables the system to estimate object rotation around two of the three dimensions -- and all at a fraction of the cost of 3D systems.

For example, a 2.5D camera-based vision system such as OnRobot Eyes can provide the depth data needed to determine how many items have been stacked in a box or whether a screw has been driven correctly.

OnRobot Eyes can easily be deployed on inspection applications. Eyes can be set up to send an alert when an error is detected, such as in the example above where one plane won't be leaving the factory. [Credit: OnRobot]

For most applications, particularly those involving collaborative automation, 2.5D cameras provide the perfect blend of usability, price, and functionality. But not all 2.5D systems are alike. So, what features should you look for to ensure compatibility with the widest possible range of applications?

Easy calibration

Calibration is a key step prior to any vision deployment process. Depending on your system, this can be complex, so look for systems that offer what's called "one-shot calibration." One-shot calibration features mean the camera can calibrate itself using information supplied by one image, removing the need to deal with multiple images and camera settings. This feature dramatically lowers the barriers to a successful deployment -- and no expert knowledge is required.

Built-in color and contour detection

Try to find 2.5D systems with built-in color and contour detection features. Especially useful in quality tasks, these features enable applications that involve sorting, inspection, or pick and place of unstructured objects based on simple color and size information input by the operator. Systems without this functionality are much more difficult and time consuming to operate. Unless you have considerable in-house expertise, systems without this functionality should be avoided.

2.5D systems like OnRobot Eyes can make sense of cluttered environments, enabling surprisingly complex vision applications. [Credit: OnRobot]

Universal compatibility

Machine vision systems are often used to help maximize the performance of existing automation. Make sure to invest in 2.5D systems that are compatible with the widest possible range of robot brands. This will ensure a degree of futureproofing if you decide to change your robot at some point down the line. Additionally, look for 2.5D systems that provide plug-and-play compatibility with the widest range of robots, as this will greatly simplify the deployment process.

Full flexibility

Some vision systems are directly integrated into robot arms, and others must be directly attached to a robot wrist or arm in order to function correctly. Both scenarios present serious limitations. Look for systems that can be mounted externally, separate from your robot. This will maximize the number of ways in which the system can be deployed. For example, a well-positione, externally mounted camera could be used to check on the condition of the equipment surrounding food products, helping you to precisely time cleaning operations. External mounting also allows you to optimize cycle time -- while your vision system handles image capture and processing, your robot can work on another task.

VIDEO: OnRobot Eyes: Adding vision to robotic applications has never been easier. [Credit: OnRobot]

Learn more about OnRobot Eyes, an adaptable 2.5D vision system, at onrobot.com/us/products/onrobot-eyes.

Published March 2024

Rate this article

View our terms of use and privacy policy